Construction sequencing involves creating a construction schedule and a chronological order of how workers will complete a construction project. It looks at how managers can assign construction tasks with appropriate resources and within a reasonable timeframe.

Here’s what you need to know about sequencing software.

Table of Contents

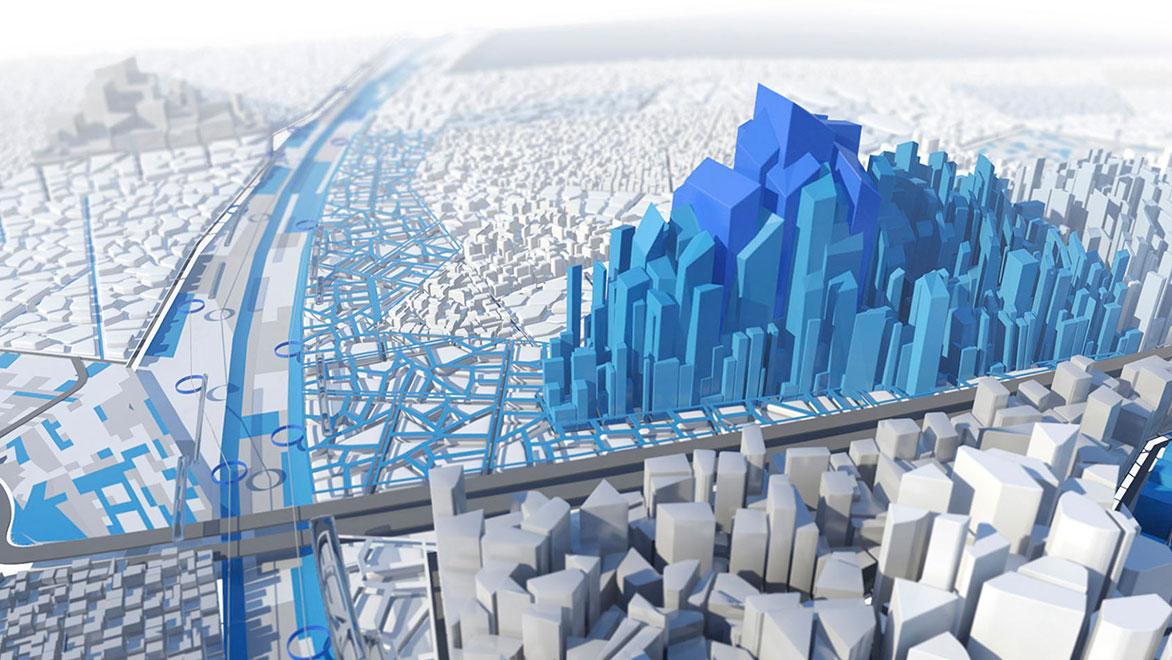

Creating a construction sequence using technology

There are two main ways contractors can create a construction sequence. The first is through traditional methods, and the second is by using sequencing software.

Traditional methods, such as Gantt chart and Excel, are outdated and no longer efficient. They’re only suitable for small construction projects. When applied to large construction projects, they cave from pressure. This makes it difficult for project managers to follow and identify risks quickly.

ALICE as a construction sequencing solution uses optioneering to create construction simulations, which identify options and alternatives that will reduce costs. Advantages of using this platform include the prevention of broken logic, the identification of infeasible schedules, and the factoring in of all construction rules and constraints.

The benefits of construction sequencing

Sequencing is crucial because it creates a chronological order that project managers should follow for a project to be completed on time.

Sequencing makes it easy for project managers to know a project’s start and end date. Contractors can then plan and create a suitable construction budget. In addition, sequencing lets the contractor know whether a project’s time frame is realistic.

Sequencing ensures the efficient allocation of resources, such as labor and equipment. This is because, for every task that has been identified, the contractor can allocate the required resources. Modern technology makes it possible for resources to be efficiently allocated, reducing costs and material waste.

Sequencing is crucial because it factors in the safety of workers. This is because project managers have a checklist that must be followed at each construction stage. These safety procedures protect the company from legal lawsuits due to negligence.

When to use construction sequencing software

There are numerous scenarios where contractors use construction sequencing software.

Material scheduling

Material scheduling identifies available material and organizes it based on created milestones. It also involves documenting materials based on their quantity, unit price, and description.

Material scheduling is important because it helps contractors avoid shortages, which can cause delays. In addition, contractors can plan their cash flow by knowing when materials are required.

Labor sequencing

Workforce scheduling is organizing labor to work on specific activities at a particular time. A labor schedule ensures that a specific task is completed within a set budget. Workforce scheduling has three main uses.

The first is to optimize the labor cost. This is done by minimizing the turnover rate, time theft, and idle times.

The second use is to maintain quality. To do this, the contractor must employ skilled labor. Unskilled labor causes numerous errors, which affect quality and increase repair costs.

Lastly, workforce sequencing is also done to ensure that workers are happy and productive. Avoid overworking your workers, because it reduces productivity.

Equipment sequencing

Contractors can use sequencing software to plan and organize how to use their equipment. Equipment such as trucks, excavators, tractors, and cranes play a key role in determining a project’s success. If equipment is not tracked or used efficiently, the project will be affected by high maintenance costs, reducing profit.

Similarly, equipment is expensive to purchase. Therefore, procurement departments need to evaluate whether leasing is cheaper than buying. In the long run, equipment sequencing helps reduce equipment costs, increasing profits.

To create a financial plan

Project owners can use sequencing software to create an accurate financial plan. Software factors in the project’s duration, labor, materials, and equipment to create a sequence. The financial plan created helps project owners develop an effective financing strategy that protects the project from financial risks. The financial strategy developed will also be based on milestones.

Another advantage of sequencing financials is that the software can recommend how to reduce costs. It can propose a simpler design or reduce costs by ensuring no over or under-allocation of resources.

To create better bids

When bidding for a government project, most contractors make the mistake of lowering their prices to have a competitive advantage. This strategy only benefits the government and not the contractor. By reducing costs, contractors affect their profit margins. Sequencing software allows contractors to find innovative ways of reducing costs without affecting their margins.

When used correctly, the sequencing platform can reduce construction times and equipment costs significantly.

To recover a stalled project

Contractors must use sequencing platforms to recover stalled projects. The platform will simulate multiple ways a project can be recovered while reducing risk. Modern platforms identify risks and develop mitigation measures that contractors can use to protect the project from stalling.

Conclusion

In conclusion, construction companies must use sequencing software to gain a competitive edge. This is because the software makes it possible to minimize construction risk and reduce costs. In addition, sequencing software makes it possible to optimize resources.